|

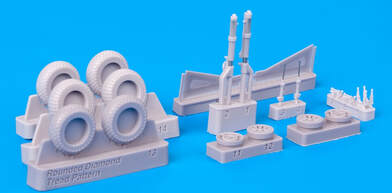

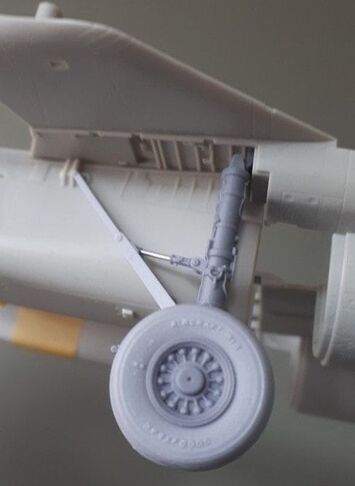

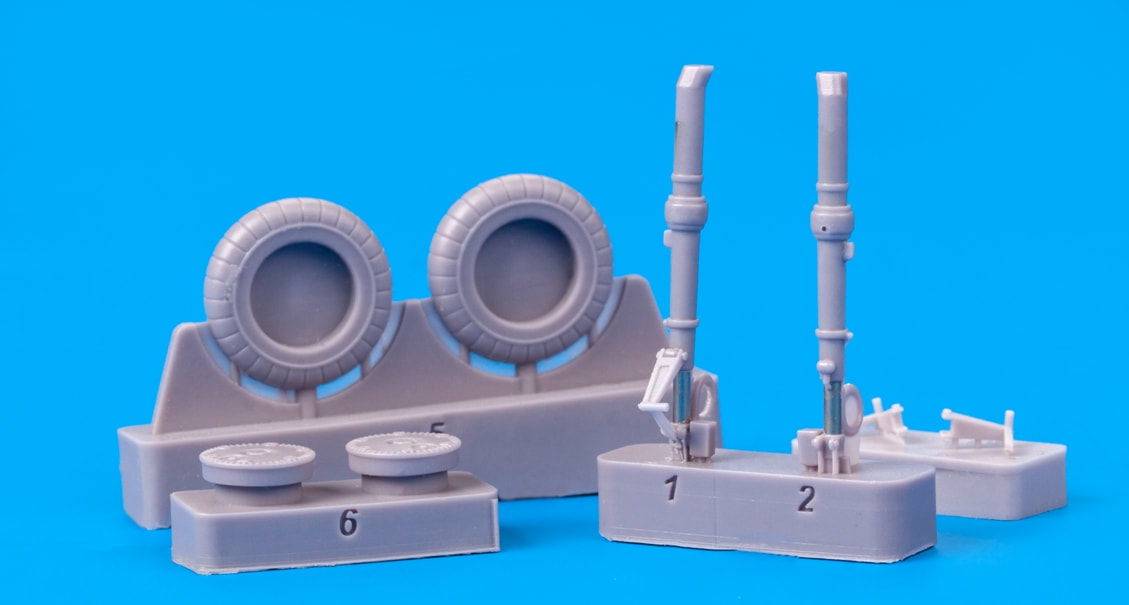

so....what's a model without a great set of legs? Essentially, Darwinism tells us that man's age old pursuit of the perfect set of legs is normal and natural! Kazan Model Dynamics proudly introduces an innovative new approach to an aspect of modelling aircraft that often falls well short of the standard of a finished build, and addresses several annoying shortcomings of what is currently available and possible. The manufacturing process culminates in landing gear legs and retraction struts with exposed metal oleos and pistons that look incredibly realistic, have no mould seams, and only require masking. Even the masking is not entirely necessary, as a gentle scraping of any paint applied will remove it without scuffing the metal. Below is our first set, covering the 1:48th scale Eduard Bf 109G-5 and Later. What you see here is the collection of eight components making up the set. In this photo, the main leg, Part No.1, has the torque links attached, but they are not glued in place. The initial concept, which has been preserved as an integral part of the product's success, required making sure that a buildable product was being sold, and part of this was deemed to be some form of deflection of those that like to use the term 'fiddly' in connection with modelling. The line between 'fiddly' and 'fidelity of detail' is clouded and overlapping, but is often used, and always used in a derogatory way. Our approach to addressing this was to make, wherever possible, any attachment of parts, especially the smaller ones, a 'friction' fit, if not an outright snap fit. This allows for very clean and tidy gluing, as well as greatly easing the process, reaping unsurpassed detail as the main benefit. The parts are still small, but that is a function of scale, and we take no responsibility for that. Above left (or top photo on your phone) is the Bf 109G, and to the right (below), the P-51D. Both are very similar in concept, but the '109 is a simpler affair. Each Bf 109 gear is made up of four parts (the fourth is the wheel hub, not visible in this shot) and the brake line is cast integrally with the leg. Several ideas were tried; this was by far the best. There is a film inside of the brake line loop and it is very easily removed due to the nature of the resin, which is non-brittle. Actually, without this resin and its pluses, this concept would've died a quick death very early on, because, for one, the torque links would have been impossible to do. In each of the above two shots, the metal forms the main bearing material, and the resin picks up the rest. The gear was load tested over extended periods of time to 300% finished model weight to ensure that the resin (love that stuff!) resisted creep where bending moments were generated. To top it off, the tests involved resin only prototypes (with no metal) and at 300% weight, the legs themselves bent, but no movement whatsoever was registered where, intuitively, the bending moment should have manifested itself. Of course, the metal that reinforces the gear and replicates the oleo piston prevents the bending that was observed in the tests. The metal extends the length of the leg, but not into the casting block, meaning no metal needs to be cut when assembling and prepping the gear. That would be mean.  This is the complete First Set for the Eduard P-51. It has the catalog number KLG4803EDU and includes three different tire patterns. The tire patterns were included to make various combinations possible from one set, and combinations for the P-51 were common in reality. Parts 3 and 4, in the foreground, are the main door retraction struts, also featuring a metal piston.  The second P-51 set, differing from the first by having three tread patterns differing from those in the First Set. This set is numbered KLG4804EDU. The fourth and final new release in this line this month covers the F-14A/B/D, designed to fit Tamiya's masterpiece of a kit. This one is a little different in its complexity, but that is defined by the fact that it is the F-14...this ain't no '109. It has a grand total of 42 parts spread over three legs, two main, one nose and most of it is snap fitting...If this sounds high, bear in mind that twelve parts of that total account for the tires and hubs alone. The legs feature all the brake and other hydraulic lines, and the exposed metal oleos speak for themselves. The centre picture shows the part as cast, and features the flat piece designed to ease demoulding and extend mould life, and subsequently, keep production costs down. It is designed for easy removal, though, and is attached to easily accessed (and cleaned up) sections of the leg, and is otherwise attached to the leg with a 60 micron film. This is easily removed and is limited to the inside edge of the leg. The nose gear was a little more complicated and as much as possible, the corresponding flat films were cast with the leg itself, in an effort to keep parts count low (ish). Most of these corresponding films (not seen here) are limited to running down the metal oleo, and clean up is not difficult at all. Again, using resin that is not brittle at all helps in this immensely. As shown, the nose gear has ten (of twelve) parts in the shot above right, and none are glued in place.... An indication of the type of engineering that went into these kits....here's the F-14 main gear leg. This is eight parts (of twelve) and only one is glued in place. The main arm is a snap fit just above the torque links (also snapped in place) and the smaller retraction strut that connects the main arm to the leg halfway up is also snapped in place. These are all free to pivot in place, prior to some nice, clean gluing. That smaller strut also features a metal piston, and frankly, these shots do not do it justice.  All of these sets are carefully designed to fit a specific kit, and that includes the locking brace for the F-14, not visible in this shot. incidentally, the F-14 set includes early, mid and late production rims, making them viable for the F-14A, B and D. The first four sets cover, as mentioned, the Bf 109G-5 and up (Eduard), the F-14 (Tamiya), and two sets for the P-51 Mustang (Eduard). The next round of releases in February will cover the Spitfire Mk. VIII, IX and XVI (Eduard - 2 sets), the F6F Hellcat (Eduard, and will include a gear length correction), the Eduard Fw 190A, and naturally, the P-38 from Tamiya. March will see the release of our next F-14 set (non-landing gear) featuring the avionic bays. This is expected to be a really good seller, and we will take advantage of the cash flow cushion by releasing some slightly more niche landing gear sets, including the MiG-3, unspatted Stukas and some Japanese types, as an experiment to see what the market desires. Of course, you can always get in touch with us directly and let us know yourself! The first four sets are in limited production now, and will go into full production second week of January. We, or at least those mutineers that work for me, are taking a Christmas break til then. We will begin taking pre-orders starting Christmas, and all orders will go out in order of receipt from the third week of January. Final prices are yet to be set, but, for the first four, they will range from $24.99US for the Bf 109G-5 to $34.99 for the Tomcat set.

0 Comments

Leave a Reply. |

Archives

February 2024

Categories |

RSS Feed

RSS Feed